- Home

- Automated Assembly System

- LED Tube Light Automated Assembly Equipment

LED Tube Light Automated Assembly Equipment

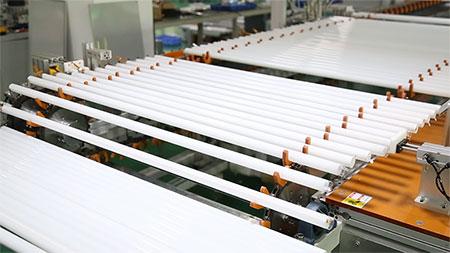

LED tube light automated assembly equipment can complete processes of dispensing, assembling, aging testing automatically, which can help you improve production efficiency, product qualification rate and reduce labor costs in T8&T5 LED tube light assembly. Take T8 LED tube light as an example, three workers are required to complete the manual assembly, with production efficiency about 500-600 pcs/h; while the same process operated by the automatic assembly equipment only requires one person, with production efficiency about 1500pcs/h.

In the automatic dispensing part, the light strips are picked and placed with suction assembly automatically, and then glued and fitted simultaneously with several sets of dispensing valves. The assembly part is highly integrated, which can realize automatic soldering of driver board, automatic soldering of the second lamp holder, tube length fixing, parallelism rectifying, wire cutting, lamp cap punching, lighting testing, etc. according to your demands.

The automated assembly equipment is specially designed for the production of T8 and T5 LED tubes of 0.6m, 0.9m and 1.2m in length. It can also be customized to process LED tubes of 1.5m.

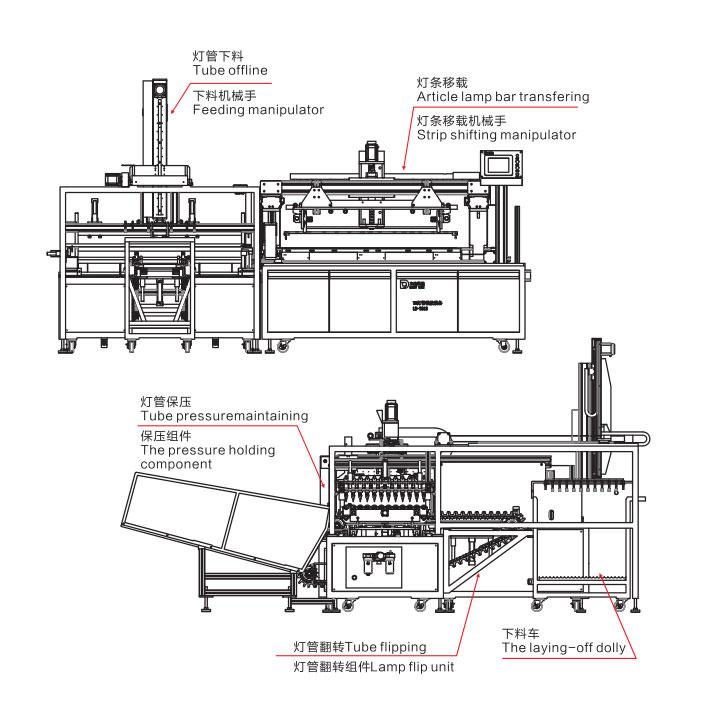

A. Automatic Fluid dispensing system

LED FPC dividing->LED strip picking->LED strip dispensing->tube pressure maintaining->tube feeding->tube flipping->tube handling->finished products

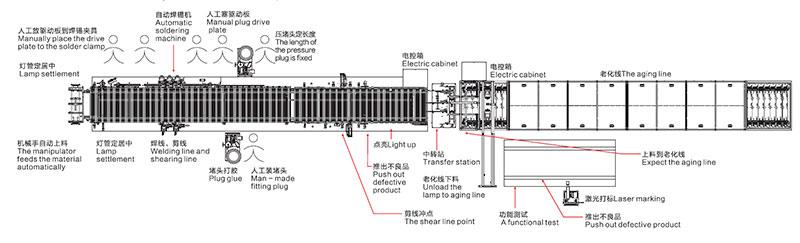

B. Automatic assembly production line

Automatic material unloading to the dolly with manipulator->automatic feeding->tube parallelism rectifying->wire cutting and soldering->automatic soldering->plug gluing->plug length fixed->lighting testing->feeding to aging line->tube aging testing->discharging from aging line->laser marking.

- With the function of automatic LED FPC dividing, 10, 11 and 12 pieces of LED FPC can be divided from one whole LED strip board with this machine according to your needs.

- The LED strips are picked and placed with suction assembly automatically.

- Automatic tube feeding via slope conveying.

- Several sets of dispensing valves can dispense and fit LED strips simultaneously.

- Automatic material unloading with sucker manipulator.

- Automatic soldering of driver board in T8 LED tube.

- Automatic wire soldering of lamp holder part.

- Lamp lighting and power testing available

1. Fluid dispensing system

| Overall dimension | L3350*W3400*H1980mm |

| Rated voltage | AC380V,50-60HZ |

| Rated power | 10Kw |

| Design capacity | 1600~1800pcs/h |

| Air pressure | 0.5-0.7MPa |

2. Assembly production line

| Overall dimension | L11300*W1900*H1600mm L11300*W1800*H1700mm |

| Working voltage | AC220V 50HZ |

| Air pressure | 0.5-0.7MPa |

| Design capacity | 1200PCS/h |

| Actual capacity | 1000PCS/h |

| Control system | PLC+human interface |

-

- No. 3, Tonghuan Road, Tongsha,Dongcheng Street, Dongguan City ,Guangdong Province,China

- Sindy Chen

- +86-769-21994338

- +86-769-21994339

- Soldering Robot Automated Assembly System

-

Screw Driving Robot

- SC-550 Screw Driving Robot

- SC-340D Screw Driving Robot

- SC-160 Screw Driving Robot

- SC-380 Screw Driving Robot

- SC-600F Screw Driving Robot

- SC-170II-C Screw Driving Robot

- SC-180II-S Screw Driving Robot

- SC-220Ⅱ Screw Driving Robot

- SC-210II-DT Screw Driving Robot

- SC-200Ⅱ-D Screw Driving Robot

- SC-190L Screw Driving Robot

- Fluid Dispensing System