- Home

- Equipment & Robot

- Screw Driving Robot

- SC-190L Screw Driving Robot

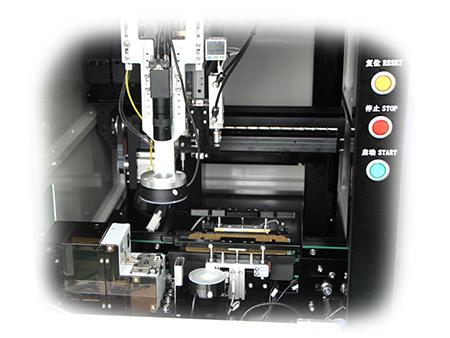

SC-190L Screw Driving Robot for In-Line Production

SC-190L screw driving robot is suitable for in-line screw fastening. Products can be conveyed into the robot without fixture, then automatically located and fastened with screws, during which the width of the conveyor can be adjusted. It is suitable for fastening small screws on various precision electronic products such as mobile phones, smart watches, tablets, camera lenses, etc. The robot can greatly improve production efficiency and save labor costs.

Characteristics

- Advanced CCD vision positioning system is adopted to correct the mark point.

- The screw points positioning is more accurate assisted by CCD, which avoids human visual errors.

- Defective screw holes can be automatically detected by CCD.

- PC motion control system is adopted, which enables visual programming and unlimited data storage.

- The machine can intelligently read the product’s CAD or Gerber data to get the coordinate value of XY.

- With a screw height displacement sensor, the height of the screw can be automatically detected.

- Intelligent screwdriver head can be set with various torsion and speed options. Both the waveform and value of torsion can be output.

- The screw driving robot realizes efficient detection of screw missing, screw slip teeth and floating lock.

Technical parameters

- Dimension: 900*520*1650mm (L*W*H)

- Working range: 170*150*70mm (X*Y*Z)

- Drive mode: 4 axis precision servo motor+precision screw

- Positioning accuracy: ±0.02mm

- Operating system: Windows 7

- Control system: PC+high precision industry CCD+high performance motion control card

- Program mode: CCD coordinate loading+CAD coordinate import

- Screw feeding mode: suction type

- Fastening speed: 2.0~2.5S / PCS,M1.2*2 screw

- Operation interface: 14 inch LCD + Keyboard + Mouse

- Power supply: 220VAC, 50HZ

- Net weight: 0.4Mpa

Inquiry

-

- No. 3, Tonghuan Road, Tongsha,Dongcheng Street, Dongguan City ,Guangdong Province,China

- Sindy Chen

- +86-769-21994338

- +86-769-21994339

- Soldering Robot Automated Assembly System

-

Screw Driving Robot

- SC-550 Screw Driving Robot

- SC-340D Screw Driving Robot

- SC-160 Screw Driving Robot

- SC-380 Screw Driving Robot

- SC-600F Screw Driving Robot

- SC-170II-C Screw Driving Robot

- SC-180II-S Screw Driving Robot

- SC-220Ⅱ Screw Driving Robot

- SC-210II-DT Screw Driving Robot

- SC-200Ⅱ-D Screw Driving Robot

- SC-190L Screw Driving Robot

- Fluid Dispensing System