- Home

- Factory Tour

Factory Tour

The workshop mainly produces parts needed by our equipment. The main processing equipment includes CNC lathes, milling machines, grinders, CNC engraving and milling machines, and wire EDM machines. We also have optical comparator and other testing equipment to control the quality of processed parts. The complete quality control procedure is carried out by professional and experienced QC employees to ensure the required quality.

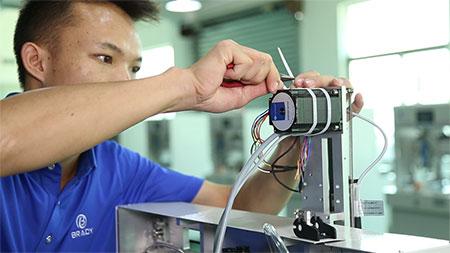

Actually, each equipment will be assembled by the professional technicians. Each process will be documented for later quality traceback when assembling. The production period of standard equipment is about 10 days. The customized automatic assembly equipment will be completed in 40~90days depending on the specific requirements.

After assembling, the equipment enters a strict debugging stage. Actually, each project will be allocated with a special software engineering team at the beginning. The team leader will summarize various problems, analyze the causes and solve them during debugging. Only when the equipment passes the debugging and the warehouse receives the factory acceptance sheet, the equipment will then be sent out.

-

- No. 3, Tonghuan Road, Tongsha,Dongcheng Street, Dongguan City ,Guangdong Province,China

- Sindy Chen

- +86-769-21994338

- +86-769-21994339

- Soldering Robot Automated Assembly System

-

Screw Driving Robot

- SC-550 Screw Driving Robot

- SC-340D Screw Driving Robot

- SC-160 Screw Driving Robot

- SC-380 Screw Driving Robot

- SC-600F Screw Driving Robot

- SC-170II-C Screw Driving Robot

- SC-180II-S Screw Driving Robot

- SC-220Ⅱ Screw Driving Robot

- SC-210II-DT Screw Driving Robot

- SC-200Ⅱ-D Screw Driving Robot

- SC-190L Screw Driving Robot

- Fluid Dispensing System